The main component of PSU is TOPSwitch-GX chip. There are produced whole line of these chips: TOP242 (weakest), TOP243, TOP244, TOP245 (used in this design), TOP246, TOP247, TOP248, TOP249 and TOP250 (Most powerful- 10A switch, up to 290W output power).

The chip is connected in typical way according to manufacturer’s recommendation. Eagle schematics is a bit skew, but it is useful and working. I highly recommend to read all application sheets for manufacturer’s site.

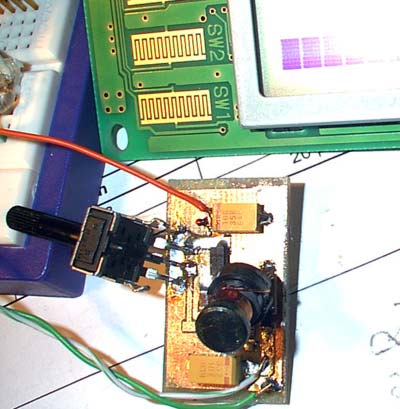

R2 resistor is already discussed in older post. Other important elements in live side are R1, D1, D2 and C2. C2 must be high voltage one, not less than 400…500V. Interesting diode D2 is P6KE170. D2, C2 and R1 are used to protect chip’s output drain for overvoltage spikes. It is leaking inductance clamping circuit. C2 and R1 are selected such, that D2 dissipated very little power except during overload conditions.

R1 is 2W power resistor. D1 is 1N4937 and is not recommended to use any other cheaper alternative. It is fast recovery rectifier, 600V, 1A (pulse 30A)

R10 sets the device current limit to 80% of typical to limit overload power. So, if your transformer and output diodes are powerful, you can short circuit PSU without any problems.

Bias current for optocoupler in live side is fed from special winding of the transformer. It is very low current, 12V winding, so the wire can be very thin. And diode D5 is very small.

The control pin components (C5, R4, C6) are not very clear for me. C6 is high frequency filter. And the rest is something used during startup. In datasheet there is the line: CONTROL pin capacitor: 47 μF, 10 V, low cost electrolytic (Do not use low ESR capacitor). But the donor PCB from some LCD monitor is with cap which looks like low ESR…

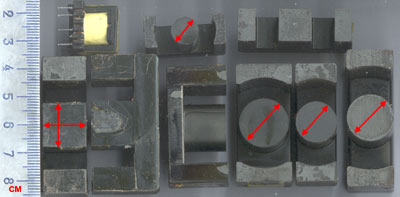

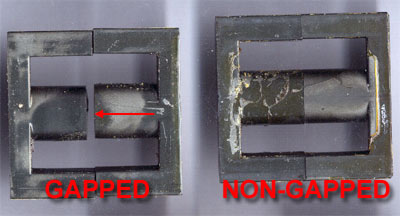

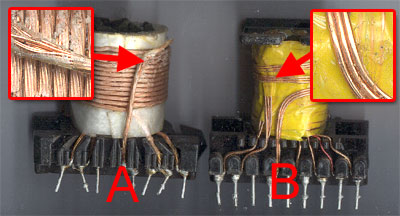

Now let’s look at the transformer.