(AI translated)

Somewhere, I mentioned that I have a photolithographic (UV-curing resin) printer. But I never mentioned that when I first bought that printer, my relatives decided to move it to another place without my knowledge because it smelled very bad to them. And the printer had resin in it… As a result, it was a complete disaster, and resin spilled everywhere, including inside the printer. After half an hour of shouting and maybe three hours of cleaning with paper, alcohol, and some foreign “some kind of mother’s” solution, I managed to clean the printer. As far as I could see, the resin did not get into the optics, the case was cleaned, and the electronics got an additional insulating layer. The printer continued to print correctly, but its appearance was no longer as it should have been. Today I turned on the printer after about five months and realized it was a disaster. The Z-motor was completely stuck. Apparently, the resin got inside the motor and finally hardened. It hardened so much that when turning with pliers, the metal screw was scraped first, and only then did the motor move a little.

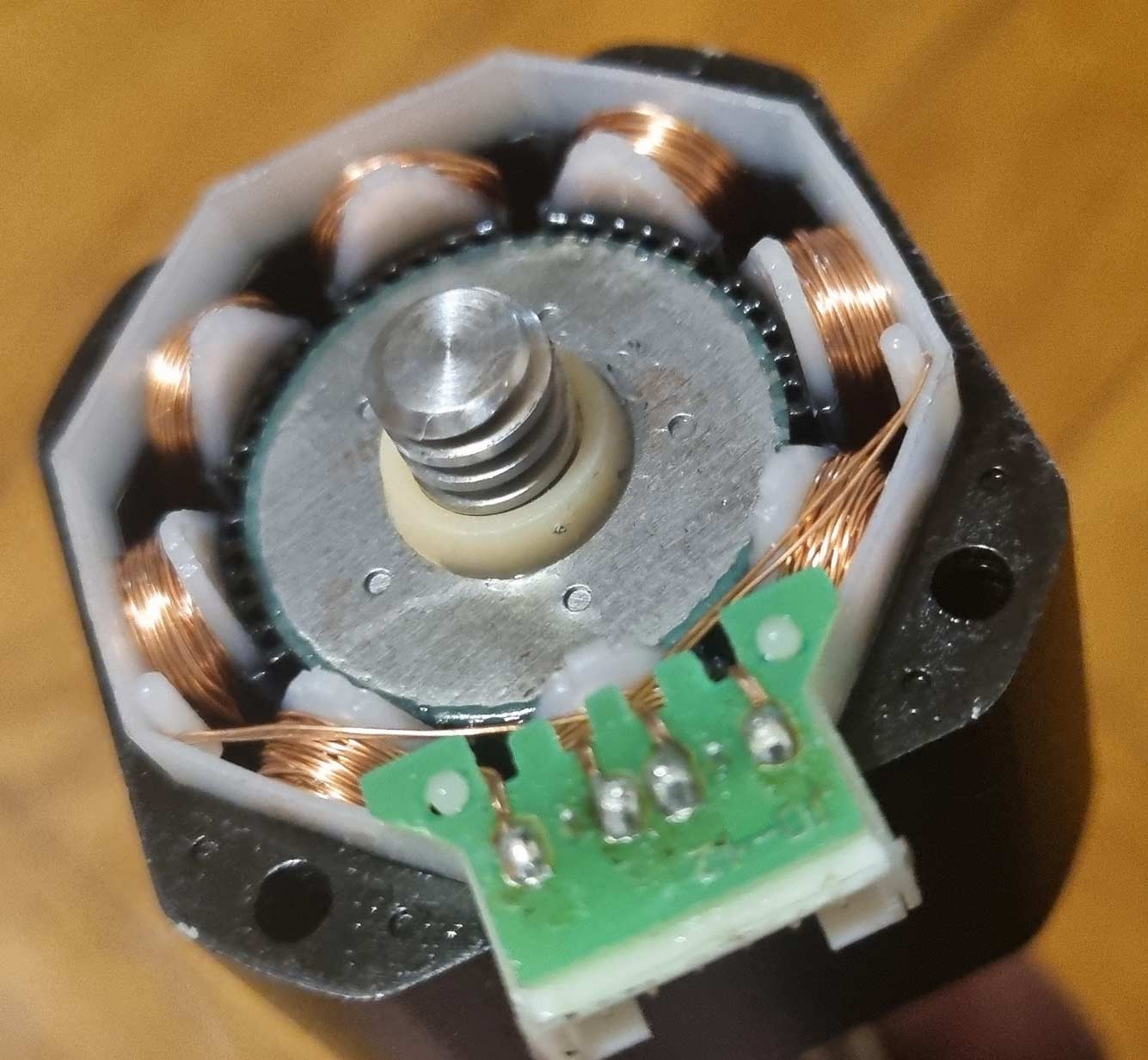

Here is the motor itself without covers, as I thought the resin glued the bearings. Unfortunately, it didn’t. You can see the working area of the screw, so we grabbed the non-working area with pliers and scratched everything there.

This motor is a 17-size NEMA standard. There was no sticker on it.

Here are some old NEMA17 motors with different winding parameters.

Their pinout is more or less standard, showing with an ohmmeter that the connection is the same. However, the old ones had a tap from the winding centers. In the Chinese one, this contact is not connected at all:

Another detail – in the Chinese motor, the 8mm screw is just pressed into the motor. There is no coupling (muff) between the motor and the screw. This means that any motor cannot be connected without turning works. It’s either a new motor or a new printer. Trying in various ways, I couldn’t loosen this motor; it was seriously stuck. Even when connected to a lathe and spun well, the motor heated up, but the resistance did not go away. The only option left was to buy because, according to all legends (and practice with old motors), when you disassemble a motor, its “mojo” – voodoo spirit (not to be confused with Mojo Jojo) evaporates. More seriously, some magnets lose their magnetism if their magnetic lines “open.”

However, the motor was as good as thrown away, so I got brave and disassembled the motor completely:

Either I was lucky, or this is some new model with neodymium magnets that don’t lose their spirit so quickly. So quickly (just in case), I sanded the resin layer from the rotor with sandpaper, and the motor started to rotate relatively freely, but the “catching” effect remained – the magnet was still strong. I was lucky because once I disassembled an old motor, and after disassembly, it started to rotate very easily and lost its strength.