I’ve noticed, that Chinese made “Blue Pill” PCB has fake chips. Some chips are with smaller ROM and RAM size, some chips behaves a bit strange. Also, several mine projects are getting bigger and bigger. Recently, I acquired several bigger chips (STM32F103RET6), from one local hardware company- they just utilized leftovers from warehouse. For this chip I designed new PCB with all pins exposed to standard 0,1″ headers, added USB connector and several mandatory elements. I squeezed all components to 5x5cm square. Minimal PCB size (for same price) is 10x10cm, so with the magic of copy-paste I quadrupled my PCB. There is option for cutting PCB in PCB-house, but it is quite expensive. Also, this extra cost increase value of PCB to such level, that I must pay the taxes for it. And the worst- I must pay “custom documents filling” fee (about 6x the small PCB price). My decision- I will cut PCB by myself.

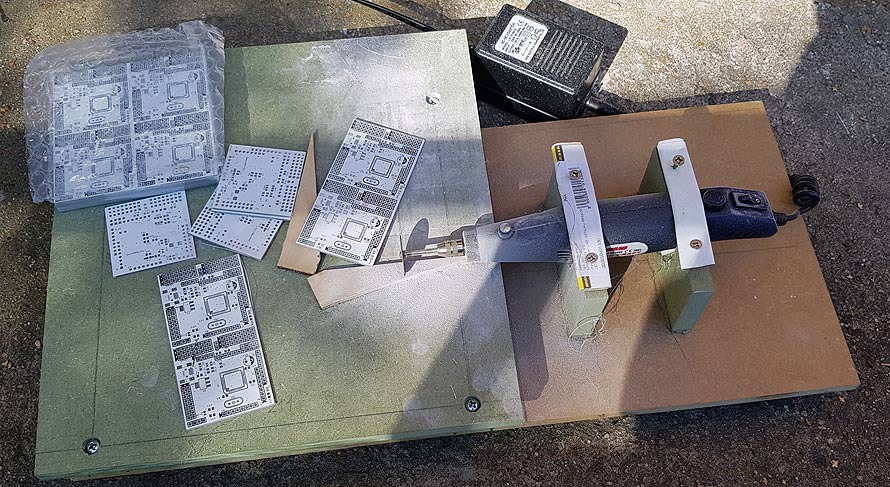

From some paper dust particle board scraps and drawer holders (sliders) I build parallel moving “table” and glued “dremel” to base. Now I can cut nice, straight lines. And main thing- the cut lines are repeatable.

When cutting, never cut whole PCB thickness at one cut. Cut half of the thickness from one size, and other half- from other side.

Beware of ugly smell and tiny glass dust. Cut in open air or with good sucking ventilation.

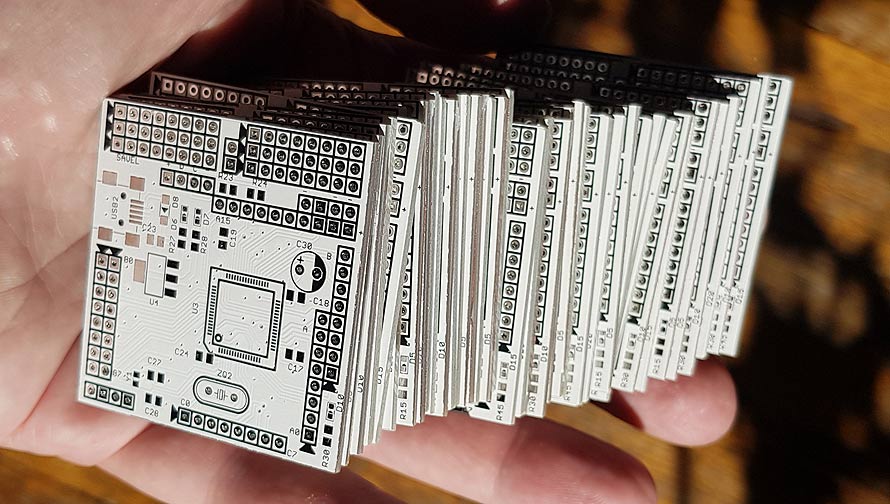

Now I have lots of PCBs for my experiments:

It will be fun, if I made mistake in PCB design.

PCB pinout and photo: