Transferred from old and some-why Google banned pages.

Chip, PCI/AGP/ISA/MCA/CPU and etc. slot desoldering from PCB board

After lots of experiments of desoldering multipin parts from PCB using fancy irons, gas torches, hot air guns and other stuff I “invented” this technology. Using this technology all parts do not get mechanical stress and PCB board is not damaged. This method is ideal for multilevel PCB. I didn’t find any damage to parts caused of using this technology. The only bad side of this technology that ALL parts are desoldered. It is impossible to desolder selected parts.

This technology is free for personal use. If you want to use this technology in industry, please contact me as it is © by Levas. 🙂

Preparing: Remove all jumpers, batteries, socket-ed parts. Also remove all plastic mounting devices used to fix board in casing. Check solder side for bent pins. Prepare grill grid and few vials for collecting fat. Better use 3 ones. One in oven, two other on floor.

Baking: Place PCB on grid detail side down. Turn on grill oven. Baking must be done only using grill. All desoldering is done by infra red radiation. Set thermostat to 180°C. This value is not very informative as it depend of oven type. distance from PCB to grill and other mysterious parameters. You only need to remember that solder melts at 160°C- 190°C (for lead solder).

Take care of good ventilation. The scent of baked PCB is quite odd and maybe toxic.

In my oven, after about 10- 15 minutes you can hear first parts falling down to vial. Shake the board to remove more parts. Not all parts falls from PCB, but you can easily remove almost all solder and the parts can be removed even from cool PCB. Take the PCB and stoke it to vial soldering side down. In vial you can see lots of solder drops. Now turn over PCB and strike again. Now almost all parts fells out from PCB. If needed, repeat again. Why we need to strike solder side down for the first time? If done in revers, drops of solder contaminate space between pin in the parts. We’ll use lots of time cleaning parts.

Note: usually keyboard, mouse and USB ports are still in PCB. The construction of these devices are with special mechanical hardness. Also sometimes you need to use screwdriver to help some parts fall down.

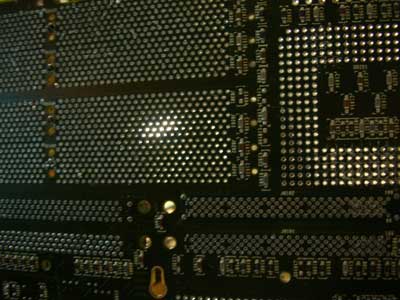

That’s all! In the image you can see that all holes in PCB are clean. Also you can see that regulators radiators are still on the board. That is because the air in the oven is lower than melting point of solder. Also these parts have some mechanical fixing. Comment: small (resistors, caps) SMD parts sometimes are left on PCB and sometimes drop with solder drops. It depends of glue type used in SMD process. Typically SMD chips are not glued to PCB.

All collected drops of solder can be casted to big drop and reused in your soldering. In case solder if “contaminated” with small SMD parts there is the problem. It is possible to sort it…Where is Cinderella? If you don’t need to salvage SMD parts, just melt big blob of solder and all SMD parts will float on the top. Just brush them away…